XSG rotary flash dryer

XSG rotary flash dryer

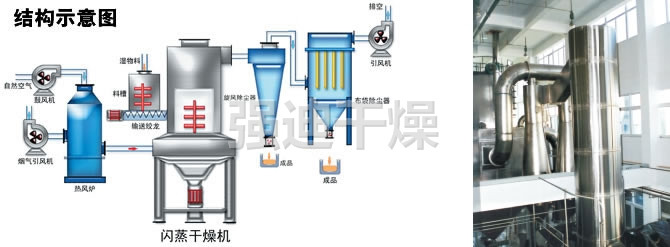

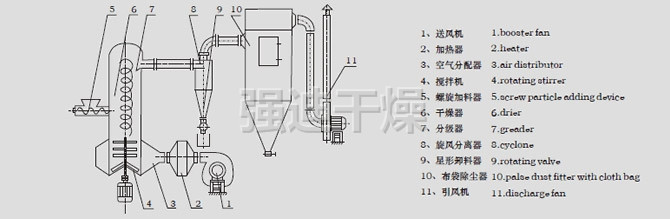

Working principle

The hot air tangent enters the bottom of the dryer and forms a strong rotating wind field under the agitator. The paste material is entered into the dryer by the spiral feeder. Under the strong action of high speed rotating stirrer, the material is dispersed under the effect of impact, friction and shear force. The bulk material is quickly crushed, and it is fully contact with hot air, heated and dried. The dry material after dehydration rises with the heat flow, and the large particles are intercepted by the classification ring. The small particles are discharged from the center of the ring, and are recycled by the cyclone separator and the dust collector. The dry or large mass material is flung to the wall by the centrifugal force, and then it falls to the bottom to be crushed and dried.

Performance characteristics

◎The combination of swirling, fluidizing, spouting and crushing grading technology.

◎Compact equipment, small size, high production efficiency, continuous production, to achieve "small equipment, large production."

◎It has high drying strength, low energy consumption and high thermal efficiency.

◎Material residence time is short and finished product quality is good. It can be used for drying heat sensitive materials.

◎Negative pressure or micro negative pressure operation, good airtight, high efficiency, eliminating environmental pollution.

Adapt to material

Organic compounds: atrazine (pesticide insecticides), lauric acid septum, benzoic acid, benzoic acid, bactericidal Dan,br />

Sodium oxalate, cellulose acetate, organic pigment and so on.

dyestuff: Anthraquinones, black iron oxide, indigo pigment, butyric acid, titanium hydroxide, zinc sulfide, various kinds of

Nitrogen dye intermediates.

Inorganic substances: borax, calcium carbonate, hydroxide, copper sulfate, iron oxide, barium carbonate, antimony oxide three,

All kinds of metal hydroxides, various heavy metal salts, synthetic cryolite and so on.

Food: soybean protein, gelatinization starch, wine trough, wheat sugar, wheat starch and so on.

technical specifications

| Model | XSG-2 | XSG-4 | XSG-6 | XSG-8 | XSG-10 | XSG-12 | XSG-16 | XSG-20 |

| Internal diameter of hostmm | 200 | 400 | 600 | 800 | 1000 | 1200 | 1600 | 2000 |

| Air volumeM3/h | 350-500 | 1150-2000 | 2450-4500 | 4450-7550 | 7000-12500 | 10000-20000 | 18000-36000 | 28200-56500 |

| Evapotranspirationkg/h | 12-17 | 40-70 | 80-150 | 150-250 | 230-4250 | 300-600 | 600-1000 | 1000-1500 |

| Maximum installed capacitykw | 10 | 20 | 40 | 65 | 85 | 105 | 150 | 230 |

| Maximum height M | 4.0 | 4.8 | 5.8 | 6.5 | 7.1 | 7.8 | 8.8 | 10.1 |

| Land area m2 | 15 | 20 | 28 | 35 | 40 | 52 | 80 | 150 |

Note: 1. the amount of water evaporation is the evaporation of water per hour when the inlet temperature is 1 80oC and the outlet temperature is 80oC.

2.In addition to the above model, special design can be made for the user.

3.The above installed capacity is standard matching, and the matching can be obviously reduced according to the different power of materials.

Handling materials and characteristics (based on type 6 flash evaporation) < /strong>

| Material name | stearic acid | Aluminum hydroxide | Zinc carbonate | monosultap | TMTD | DSD Acid | Ferric oxide red | Two antimony oxide | Cuprous chloride | White and black |

| Air inlet temperatureoC | 150 | 180 | 150 | 120 | 140 | 150 | 200 | 180 | 200 | 280 |

| Initial moisture content% | 80 | 55 | 80 | 30 | 65 | 60 | 60 | 45 | 30 | 85 |

| Final moisture content% | 0.5 | 1.5 | 1.0 | 1.0 | 0.5 | 0.5 | 0.5 | 1.0 | 3.0 | 5.0 |

| Actual drying capacitykg/h | 140-160 | 250-280 | 130-170 | 80-110 | 80-120 | 80-120 | 300-350 | 280-320 | 290-310 | 250-300 |

| Material name | accelerator | Oil soluble ink | Manganese zinc | Blue blue | Calcium citrate | Superfine calcium carbonate | Mud treatment agent | Sodium isocyanurate two | Sodium isocyanurate three |

| Air inlet temperatureoC | 150 | 150 | 120 | 150 | 140 | 160 | 200 | 180 | 150 |

| Initial moisture content% | 60 | 45 | 30 | 55 | 40 | 70 | 75 | 25 | 30 |

| Final moisture content% | 0.5 | 2.0 | 1.0 | 1.0 | 1.0 | 1.5 | 5.0 | 0.2-2 | 1.0 |

| Actual drying capacity kg/h | 80-110 | 350-380 | 120-150 | 160-180 | 300-350 | 430-470 | 290-310 | 80-120 | 90-150 |

-

XSG rotary flash dryer

-

XSG rotary flash dryer

-

XSG rotary flash dryer

-

XSG rotary flash dryer

-

XSG rotary flash dryer

-

XSG rotary flash dryer

- 2016-08-18 > Silicon carbide dry production line

- 2017-12-27 > A special flash dryer for yeast feed additive

- 2017-12-27 > Special drying project of glyphosate

- 2017-12-20 > Special drying equipment for titanium and white powder

- 2016-08-05 > Xinjiang agricultural and sideline product net belt dryer delivery

- 2016-08-05 > Shenyang Chemical General plant has successfully ordered 4 large 96 square vacuum drying machines.

- 2016-08-05 > Qiang Di is drying with the Chinese Academy of Sciences, making two large flash dryer.

- 2016-08-05 > The hollow paddle dryer ordered by Qinghai Saline Lake has been successfully shipped

- 2016-08-05 > What trends should enterprises grasp to improve spray drying?

- 2016-08-05 > Liaoyang pigment factory orders our complete set of pigment drying equipment.

- 2016-08-05 > Improved vacuum dryer promotes green upgrading of bulk drug production

- 2016-08-05 > Necessary conditions for safe use of hot air circulating oven

- 2016-08-05 > The propeller machine industry is optimistic about the blade dryer

- 2016-08-05 > Why does the dry equipment industry don't see "Big Macs"