ZLG series vibrating fluidized bed dryer

ZLG series vibrating fluidized bed dryer

Working principle

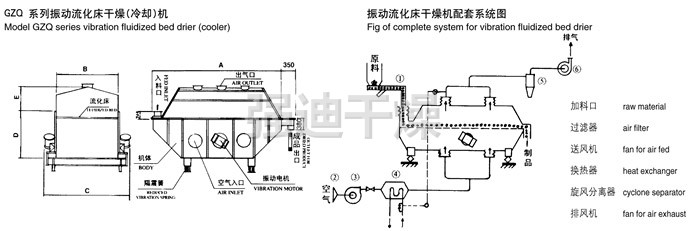

The material is imported into the machine. Under the action of vibration force, the material is thrown along the horizontal fluidized bed, moving forward continuously. After the hot air passes through the fluidized bed with the same wet material, the wet air is discharged by the exhaust air 1:3 after the cyclone separator is dedusting. The dry material is discharged from the discharge inlet.

Performance characteristics

◎Vibration source is driven by vibrating motor, running smoothly, easy to maintain, low noise and long life.

◎Uniform fluidization, no dead space and blow through phenomenon, and uniform drying and cooling products can be obtained.

◎Good adjustability and wide application. The thickness of the material layer and the movement speed inside the machine and the full amplitude change can be adjusted stepless. <

br />

◎The damage to the surface of the material is small. It can be used for drying the fragile materials, and when the particles are irregular, it will not affect the working effect.

◎The fully enclosed structure is adopted to effectively prevent cross infection between material and air and clean operation environment.

◎The mechanical efficiency and thermal efficiency are high, and the energy saving effect is good. It can save energy by 30 1 60% compared with the general drying device.

Adapt to material

It is suitable for drying, cooling and other operations of powdery and granular materials in chemical industry, pharmaceutical industry, food industry, dehydrated vegetable, grain and mineral industry. Such as: citric acid, monosodium glutamate, borax, ammonium sulfate, compound fertilizer, radish, soybean meal, distiller's grains, seeds, slag, granulated sugar and so on. <

br />

technical specifications

|

size Model |

A | B | C | D | E | F | weight(kg) |

| ZLG3×0.30 | 3000 | 300 | 1350 | 900 | 430 | 1650 | 1250 |

| ZLG4.5×0.30 | 4500 | 300 | 1350 | 900 | 430 | 1650 | 1250 |

| ZLG4.5×0.45 | 4500 | 450 | 1550 | 950 | 430 | 1700 | 1670 |

| ZLG4.5×0.60 | 4500 | 600 | 1650 | 950 | 430 | 1700 | 1670 |

| ZLG6×0.45 | 6000 | 450 | 1650 | 950 | 430 | 1700 | 2100 |

| ZLG6×0.60 | 6000 | 600 | 1700 | 1000 | 500 | 1700 | 2410 |

| ZLG6×0.75 | 6000 | 750 | 1850 | 1000 | 600 | 1850 | 2840 |

| ZLG6×0.9 | 6000 | 900 | 2000 | 1000 | 600 | 1850 | 3160 |

| ZLG7.5×0.60 | 7500 | 600 | 1850 | 1000 | 600 | 1850 | 3200 |

| ZLG7.5×0.75 | 7500 | 750 | 2000 | 1000 | 600 | 1850 | 3600 |

| ZLG7.5×0.9 | 7500 | 900 | 2100 | 1000 | 600 | 1850 | 4140 |

| ZLG7.5×1.2 | 7500 | 1200 | 2500 | 1150 | 800 | 2050 | 5190 |

| Model |

Fluidized-bed area (M2) |

Air inlet temperature (oC) |

Air outlet temperature (oC) |

Evaporation capacity (kg) |

Vibratory motor | |

| Model | power Kw | |||||

| ZLG3×0.30 | 0.9 | 70-140 | 40-70 | 20-35 | ZDS31-6 | 0.8×2 |

| ZLG4.5×0.30 | 1.35 | 70-140 | 40-70 | 35-50 | ZDS31-6 | 0.8×2 |

| ZLG4.5×0.45 | 2.025 | 70-140 | 40-70 | 50-70 | ZDS32-6 | 1.1×2 |

| ZLG4.5×0.60 | 2.7 | 70-140 | 40-70 | 70-90 | ZDS32-6 | 1.1×2 |

| ZLG6×0.45 | 2.7 | 70-140 | 40-70 | 80-100 | ZDS41-6 | 1.5×2 |

| ZLG6×0.60 | 3.6 | 70-140 | 40-70 | 100-130 | ZDS41-6 | 1.5×2 |

| ZLG6×0.75 | 4.5 | 70-140 | 40-70 | 120-140 | ZDS42-6 | 2.2×2 |

| ZLG6×0.9 | 5.4 | 70-140 | 40-70 | 140-170 | ZDS42-6 | 2.2×2 |

| ZLG7.5×0.60 | 4.5 | 70-140 | 40-70 | 130-150 | ZDS42-6 | 2.2×2 |

| ZLG7.5×0.75 | 5.625 | 70-140 | 40-70 | 150-180 | ZDS51-6 | 3.0×2 |

| ZLG7.5×0.9 | 6.75 | 70-140 | 40-70 | 160-210 | ZDS51-6 | 3.0×2 |

| ZLG7.5×1.2 | 9 | 70-140 | 40-70 | 200-260 | ZDS51-6 | 3.0×2 |

★The above evaporation is the maximum amount of evaporation.

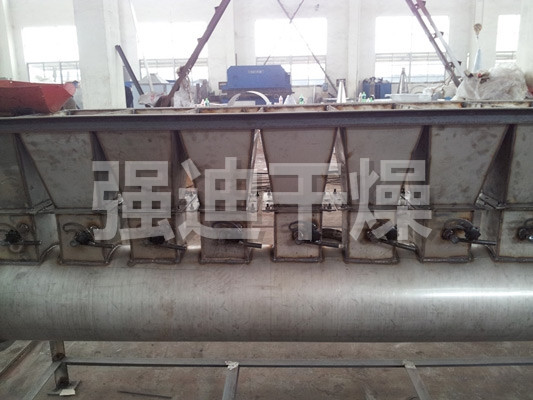

Schematic diagram

-

ZLG series vibrating fluidized bed dryer

-

ZLG series vibrating fluidized bed dryer

-

ZLG series vibrating fluidized bed dryer

-

ZLG series vibrating fluidized bed dryer

-

ZLG series vibrating fluidized bed dryer

-

ZLG series vibrating fluidized bed dryer

- 2017-12-27 > Medical horizontal fluidized bed dryer

- 2017-12-27 > Special vibrating fluidized bed for bread crumbs

- 2016-08-05 > Xinjiang agricultural and sideline product net belt dryer delivery

- 2016-08-05 > Shenyang Chemical General plant has successfully ordered 4 large 96 square vacuum drying machines.

- 2016-08-05 > Qiang Di is drying with the Chinese Academy of Sciences, making two large flash dryer.

- 2016-08-05 > The hollow paddle dryer ordered by Qinghai Saline Lake has been successfully shipped

- 2016-08-05 > What trends should enterprises grasp to improve spray drying?

- 2016-08-05 > Liaoyang pigment factory orders our complete set of pigment drying equipment.

- 2016-08-05 > Improved vacuum dryer promotes green upgrading of bulk drug production

- 2016-08-05 > Necessary conditions for safe use of hot air circulating oven

- 2016-08-05 > The propeller machine industry is optimistic about the blade dryer

- 2016-08-05 > Why does the dry equipment industry don't see "Big Macs"