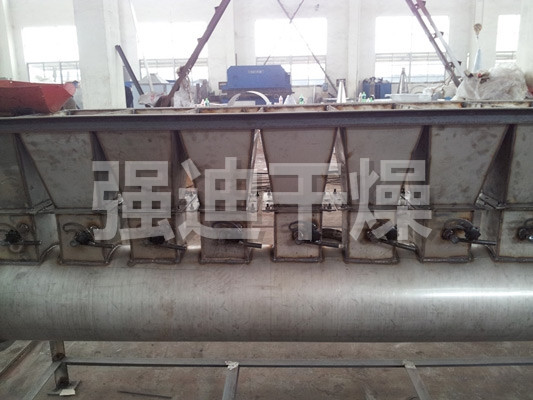

XF Series Horizontal Fluidizing Dryer

XF Series Horizontal Fluidizing Dryer

Product introduction

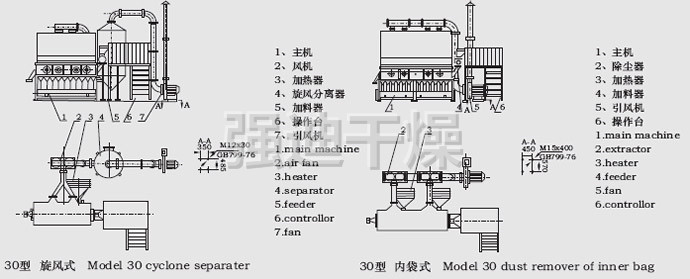

Fluidizing drier is also called as fluidized-bed. It consists of air filter , heater ,fluidized-bed main machine, feeder , cyclone separator , cloth bag duster ,high-pressure centrifuge fan and operation table. Because the properties of raw materials exist dif ference, when equip the dust removing equipment, it should consider the practical need. It can select cyclone separator and cloth bag duster at the same time or one of them. In general speaking, it needs to select cyclone

separator only for raw material that is large in specific gravity and cloth bag dusterfor powder and small granule raw materials that is light in specific gravity .Meanwhile there is air feeding device and belt conveyor for selection.

Separated granule solid raw material is fed into fluidized-bed drier through feeder. Fresh air through filtering and heating is sent to the bottom of fluidized-bed by fan and contacts with solid raw material on distributing plate. In this way the fluidized state is formed and the heat exchange between air and solid is carried out. The dried raw material is discharged from outlet and wasted gas is exhausted from the top of fluidized-bed where catches solid powder through cyclone separator , cloth bag duster .

Steam, electricity or hot air furnace can be used (it can be supplied as request).

Working principle

The clean and hot air enters into fluid bed through distributor of valve plate.The wet material is fed from the feeder forms the fluid state by hot air .Because of the wide contact between hot air and raw materials, the time of drying is short. If use continuous type, the material enters from the front of bed, fluidized in bed for several minutes, and float another side of bed. Themachine works in negative pressure.

Adapt to material

◎Drying operations for pharmaceutical and pharmaceutical raw materials, food, grain processing and feed. Such as: drying and dehumidification of raw materials, tablet particles, traditional Chinese medicine granules, health food, beverage powder, corn germ, feed, plastic resin, citric acid and other powdery materials. The suitable particle size is generally 0.1 to 6mm, and the best particle size is 0.5 to 3mm.

Installation instructions

◎The equipment needs to be leveled and fixed with bottom screws, and all parts are well sealed.

◎The fan can be placed outside or in the self built silencer. The layout of the plane can be adjusted according to the specific circumstances.

Technical parameters

|

Specification model technical parameter |

XF0.25-1 (primaryXF10) |

XF0.25-2 (primaryXF20) |

XF0.25-3 (primaryXF30) |

XF0.25-6 | XF0.3-2 | XF0.3-4 | XF0.3-6 | XF0.3-8 | XF0.3-10 | XF0.4-4 | XF0.4-6 |

| Bed area(m2) | 0.25 | 0.5 | 1.0 | 1.5 | 0.6 | 1.2 | 1.8 | 2.4 | 3.0 | 1.6 | 2.4 |

| Drying capacity(kg h2O/h) | 10-15 | 20-25 | 30-45 | 52-75 | -30 | 42-60 | 63-90 | 84-120 | 105-150 | 56-80 | 84 |

| Fan power(kw) | 5.5 | 7.5 | 15 | 22 | 7.5 | 18.5 | 30 | 37 | 48 | 30 | 37 |

| Air inlet temperature(oC) | 120-140 | 120-140 | 120-140 | 120-140 | 120-140 | 120-140 | 120-140 | 120-140 | 120-140 | 120-140 | 120-140 |

| Material temperature(oC) | 40-60 | 40-60 | 40-60 | 40-60 | 40-60 | 40-60 | 40-60 | 40-60 | 40-60 | 40-60 | 40-60 |

| Shape size (Mainframe) long * width * high (m) | 1×0.6 | 2×0.6 | 4×0.6 | 6×0.6 | 2×0.70 | 4×0.7 | 6×0.7 | 8×0.7 | 10×0.7 | 4×1 | 6×1 |

| Area covered(m2) | 18×3.35 | 25×3.35 | 35×3.35 | 40×3.35 | 25×3.4 | 38×3.4 | 45×3.4 | 56×3.4 | 70×3.4 | 18×3.58 | 56×3.58 |

|

Specification model technical parameter |

XF0.4-8 | XF0.4-10 | XF0.4-12 |

XF0.5-4 (primaryXF50) |

XF0.5-6 | XF0.5-8 | XF0.5-10 | XF0.5-12 | XF0.5-14 | XF0.5-16 | XF0.5-18 |

| Bed area(m2) | 3.2 | 4.0 | 4.8 | 2.0 | 3.0 | 4.0 | 5.0 | 6.0 | 7.0 | 8.0 | 9.0 |

| Drying capacity(kg h2O/h) | 112-160 | 140-200 | 168-240 | 70-100 | 140-200 | 140-200 | 175-250 | 210-300 | 245-350 | 280-400 | 315-450 |

| Fan power(kw) | 44 | 66 | 66 | 30 | 66 | 66 | 90 | 90 | 150 | 150 | 165 |

| Air inlet temperature(oC) | 120-140 | 120-140 | 120-140 | 120-140 | 120-140 | 120-140 | 120-140 | 120-140 | 120-140 | 120-140 | 120-140 |

| Material temperature(oC) | 40-60 | 40-60 | 40-60 | 40-60 | 40-60 | 40-60 | 40-60 |

40-60 |

40-60 | 40-60 | 40-60 |

| Shape size (Mainframe) long * width * high (m) | 8×1 | 10×1 | 12×1.2 | 4×1.2 | 8×1.2 | 8×1.2 | 10×1.2 | 12×1.2 | 14×1.2 | 16×1.2 | 18×1.2 |

| Area covered(m2) | 74×3.58 | 82×3.58 | 96×4.1 | 50×4.1 | 70×4.1 | 82×4.1 | 100×4.1 | 140×4.1 | 180×4.1 | 225×4.1 | 268×4.1 |

Note:一. Feeding mode: 1. star feeding; 2. star feeding and pneumatic conveying; 3. belt conveying; 4. user self determined.

二.Automatic production can be realized.三.In addition to the above models, special designs can be made for users.四.Depending on the material, the power of the fan is different.

Schematic diagram

-

XF Series Horizontal Fluidizing Dryer

-

XF Series Horizontal Fluidizing Dryer

-

XF Series Horizontal Fluidizing Dryer

-

XF Series Horizontal Fluidizing Dryer

-

XF Series Horizontal Fluidizing Dryer

-

XF Series Horizontal Fluidizing Dryer