SZG Series Double Cone Rotating Vacuum Dryer

SZG Series Double Cone Rotating Vacuum Dryer

Product overview

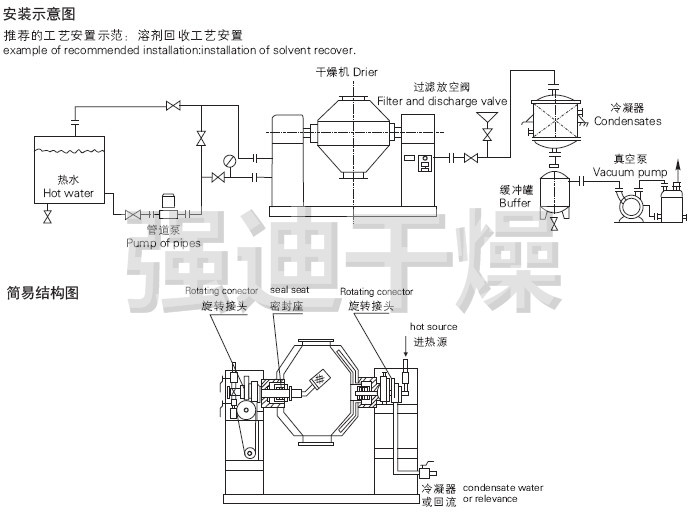

SZG double cone vacuum dryer is a new generation of drying equipment developed in our factory, which is developed by the same kind of domestic product technology. The double cone vacuum adopts the elastic link of belt and chain two, so the equipment runs smoothly. The specially designed technology fully embodies the good concentricity of the two pivot, and the heat medium and vacuum system adopt reliable mechanical seals or rotary joints of American technology. On this basis, we developed SZG-A, which can be stepless speed regulation and constant temperature control.

As a professional drying equipment manufacturer, our products are supplied from high temperature heat conducting oil to heat medium, medium temperature steam and low temperature hot water. When drying viscous materials, our factory will specially design "copy board" mechanism or set up balls for you in the tank.

Working principle

◎Let heat source(for example,low pressure steam or thermal oil)pass through the sealed Jacket The heat will be transmitted to raw material to be dried through inner shell;

◎Under driving of power,the tank is rotated slowly and the raw material inside it is mixed continuously.The purpose of reinforced drying can be realized;

◎The raw mate rial is under vacuum The drop of steam pressure makes the moisture(solvent)at the sudace of raw material become saturation and will evaporate The solvent will be discharged th rough vacuum pump and recovered in time The inne r moistu re(solvent)of raw material will infiltrate,evaporate and discharge continuously The th ree processes are carried out unceasingly and the purpose of drying can be realized within a shon time.

Performance characteristics

◎When oil is used to heat,use automatic constant temperature control.It can be used for drying biology products and mine Its temperatu re of operation can be adjusted form 20—160oC.

◎Compared to ordinal d ryer,its heat efficiency will be 2 times higher.

◎The heat is indirect So the raw material can not be polluted.

◎It is in conformity with the requi rement of GMR It is easy in washing and maintenance.

Adapt to material

It is applicable to the powder, granular and fiber concentration, mixing, drying and low temperature drying materials (such as biochemical products) in chemical, pharmaceutical, food and other industries. It is more suitable for the drying of easily oxidizing, volatile, thermosensitive, strongly irritation, toxic materials and materials that are not allowed to destroy the crystal.

|

Specifications Name |

100 | 350 | 500 | 750 | 1000 | 1500 | 2000 | 3500 | 4500 | 5000 |

| Tank volume | 100 | 350 | 500 | 750 | 1000 | 1500 | 2000 | 3500 | 4500 | 5000 |

| Loading volume (L) | ≤50 | ≤175 | ≤250 | ≤375 | ≤500 | ≤750 | ≤1000 | ≤1750 | ≤2250 | ≤2500 |

| Heating area (m2) | 1.16 | 2 | 2.63 | 3.5 | 4.61 | 5.58 | 7.5 | 11.2 | 13.1 | 14.1 |

| speed (rpm) | 4 - 6 | |||||||||

| Motor power (kw) | 0.75 | 1.1 | 1.5 | 2 | 3 | 3 | 4 | 5.5 | 7.5 | 11 |

| Area length * width (mm) | 2160×800 | 2260×800 | 2350×800 | 2560×1000 | 2860×1300 | 3060×1300 | 3260×1400 | 3760×1800 | 3960×2000 | 4400×2500 |

| Gyration height (mm) | 1750 | 2100 | 2250 | 2490 | 2800 | 2940 | 2990 | 3490 | 4100 | 4200 |

|

Design pressure in tank (MPa) |

-0.1-0.15 | |||||||||

| Design pressure of jacket(MPa) | ≤0.3 | |||||||||

| working temperature (oC) | Inside of the tank≤85 Jacket≤140 | |||||||||

| When the condenser is used, the vacuum pump, | 2X-15A | 2X-15A | 2X-30A | 2X-30A | 2X-70A | JZJX300-8 | JZJX300-4 | JZJX600-8 | JZJX600-4 | JZJX300-4 |

| Model, power | 2KW | 2KW | 3KW | 3KW | 505KW | 7KW | 9.5KW | 11KW | 20.5KW | 22KW |

| When the condenser is not used, the vacuum pump, | SK-0.4 | SK-0.8 | SK-0.8 | SK-2.7B | SK-2.7B | SK-3 | SK-6 | SK-6 | SK-9 | SK-10 |

| Model, power | 1.5KW | 2.2KW | 2.2KW | 4KW | 4KW | 5.5KW | 11KW | 11KW | 15KW | 18.5KW |

| Weight (kg) | 800 | 1100 | 1200 | 1500 | 2800 | 3300 | 3600 | 6400 | 7500 | 8600 |

Note: the material loading coefficient can be increased or reduced for materials with large volume before and after drying.

-

SZG Series Double Cone Rotating Vacuum Dryer

-

SZG Series Double Cone Rotating Vacuum Dryer

-

SZG Series Double Cone Rotating Vacuum Dryer

-

SZG Series Double Cone Rotating Vacuum Dryer

-

SZG Series Double Cone Rotating Vacuum Dryer

-

SZG Series Double Cone Rotating Vacuum Dryer

- 2016-08-18 > Battery material drying engineering

- 2017-12-27 > Special dryer for lithium phosphate lithium-ion

- 2016-08-05 > Xinjiang agricultural and sideline product net belt dryer delivery

- 2016-08-05 > Shenyang Chemical General plant has successfully ordered 4 large 96 square vacuum drying machines.

- 2016-08-05 > Qiang Di is drying with the Chinese Academy of Sciences, making two large flash dryer.

- 2016-08-05 > The hollow paddle dryer ordered by Qinghai Saline Lake has been successfully shipped

- 2016-08-05 > What trends should enterprises grasp to improve spray drying?

- 2016-08-05 > Liaoyang pigment factory orders our complete set of pigment drying equipment.

- 2016-08-05 > Improved vacuum dryer promotes green upgrading of bulk drug production

- 2016-08-05 > Necessary conditions for safe use of hot air circulating oven

- 2016-08-05 > The propeller machine industry is optimistic about the blade dryer

- 2016-08-05 > Why does the dry equipment industry don't see "Big Macs"