KJG hollow blade dryer

KJG hollow blade dryer

Product introduction

The product can be heated or cooled indirectly for paste, granular, powdery and slurry materials, and can be used for drying, cooling, heating, sterilizing, reaction, and low temperature combustion. The special wedge type mixing heat transfer blade has high heat transfer efficiency and self cleaning function of the heat transfer surface.

Working principle

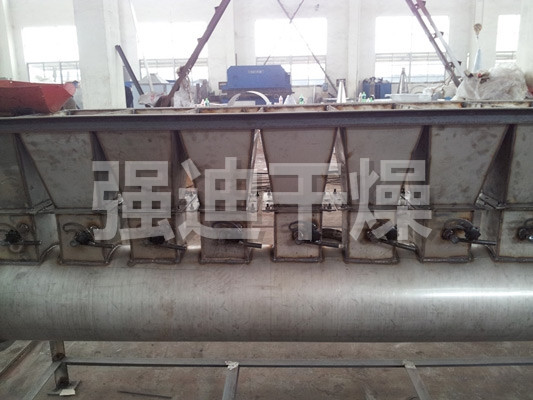

The hollow shaft is densely arranged with wedge-shaped hollow leaves, and the heat medium passes through the hollow shaft to flow through the pulp leaves. The heat transfer area in the effective volume of the unit is very large. The temperature of the hot medium from -40 to 320 C can be either water vapor or liquid type: hot water, heat conducting oil, etc. Indirect conduction heating does not carry air to carry heat, and heat is used to heat the material. The heat loss is only the heat dissipation from the insulation layer to the environment. The heat transfer surface of the wedge shaped blade has a self cleaning function. The relative movement of the material particles and the wedge surface produces a scrubbing effect, which can wash off the attached material on the wedge surface and keep the clean heat transfer surface in operation. The shell of the pulp dryer is an Omega type, and two to four hollow stirring shafts are generally arranged inside the shell. The shell has a sealed end cover and an upper cover to prevent the material dust from escaping and fully play its role.

Through the rotating joint, the heat transfer medium flows through the shell jacket and the hollow mixing shaft. The hollow mixing shaft has different internal structure according to the type of hot medium, so as to ensure the best heat transfer effect.

Performance characteristics

◎The energy consumption of the dryer is low: because of the indirect heating, no large amount of air is carried away to take away the heat, and the outer wall of the dryer is also set to heat insulation layer. For the slurry, the evaporation of 1kg water is only 1.2kg steam.

◎The system is low in cost: the huge heat transfer surface in the effective volume of the unit shortens the processing time and reduces the equipment size. Greatly reduced the construction area and building space. <

br />

◎Wide range of processing materials: using different heat medium, can not only deal with heat sensitive materials, but also can handle materials requiring high temperature treatment. Common media include steam, heat conducting oil, hot water, cooling water and so on. <

br />

It can be operated continuously or intermittently, and can be applied in many fields.

◎Environmental pollution is small: no air is used, and dust materials are seldom entrained. The vaporization of the material is very small, so it is easy to deal with. For contaminated materials or solvent recovery conditions,

The closed loop cycle.

◎The cost of operation is low: the structure. The wear amount is small and the maintenance cost is very low.

◎Operation stability: due to the special compression of the wedge type pulp - expansion and mixing, the material particles are fully contacted with the heat transfer surface. In the axial section, the temperature, humidity and mixing degree of the material are very small, thus ensuring the stability of the process.

Adapt to material

The pulp dryer has been successfully applied to food, chemical, petrochemical, dyestuff, industrial sludge and other fields. The characteristics of heat transfer, cooling, and agitation of the equipment make it possible to complete the following unit operations: combustion (low temperature), cooling, drying (solvent recovery) heating (melting), reaction and sterilization. The stirring blade is also the heat transfer surface, which increases the heat transfer area in the unit effective volume and shortens the processing time. The heat transfer surface of the wedge type pulp has a self cleaning function. Compression - expansion and mixing to mix the material evenly. The material flows along the axial direction into "piston flow", and the temperature, humidity and mixing gradient of material are very small in the axial section. Low temperature combustion can be accomplished by using heat conducting oil as a hot medium pulp dryer. For example, two water calcium sulfate (Ca2SO4? 2H2O) is converted into semi hydrated calcium sulfate (Ca2SO4? 1/22H2O). Sodium bicarbonate (NaHCO3) was calcined into soda ash (Na2HCO3). The cooling medium, such as water and cooling brine, can be used for cooling. For example, the pulp and leaf cooling machine used in the soda industry instead of the old air cooling soda machine saves energy and tail gas treatment equipment and reduces the operation cost. Drying, the most important function of equipment, does not use hot air, so that solvent recovery, energy consumption and environmental control are in an easy to handle ideal state. It is especially suitable for recovering solvents, inflammable and oxidizing heat sensitive materials. It has been widely used in fine chemical industry, petrochemical industry and dyestuff industry. The uniformity of temperature, humidity and mixing degree in the axial range makes the equipment useful for heating or melting or for some solid materials to react. It has been successfully used in compound fertilizer and modified starch industry. The pulp dryer can be used for sterilization of food and flour. The large heating area in the effective volume of the unit will quickly heat the material to the sterilization temperature, avoiding the long time heating and changing the quality of the material.

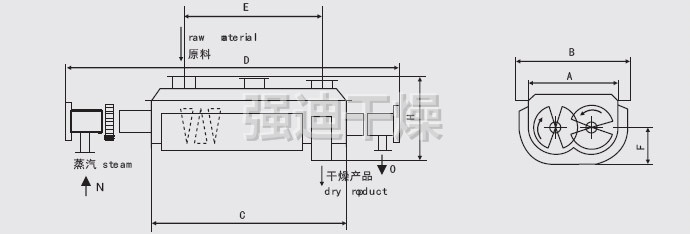

technical specifications

|

project 型号 |

KJG3 | KJG9 | KJG13 | KJG18 | KJG29 | KJG41 | KJG52 | KJG68 | KJG81 | KJG95 | KJG110 |

| Heat transfer area(m2) | 3 | 9 | 13 | 18 | 29 | 41 | 52 | 68 | 81 | 95 | 110 |

| Effective volume(m3) | 0.06 | 0.32 | 0.59 | 1.09 | 1.85 | 2.8 | 3.96 | 5.21 | 6.43 | 8.07 | 9.46 |

| Speed range(rmp) | 15-30 | 10-25 | 10-25 | 10-20 | 10-20 | 10-20 | 10-20 | 10-20 | 5-15 | 5-15 | 5-10 |

| power(kw) | 2.2 | 4 | 5.5 | 7.5 | 11 | 15 | 30 | 45 | 55 | 75 | 95 |

| Body widthA(mm) | 306 | 584 | 762 | 940 | 1118 | 1296 | 1476 | 1652 | 1828 | 2032 | 2210 |

| Total widthB(mm) | 736 | 841 | 1066 | 1320 | 1474 | 1676 | 1854 | 2134 | 1186 | 2438 | 2668 |

| Body widthC(mm) | 1956 | 2820 | 3048 | 3328 | 4114 | 4724 | 5258 | 5842 | 6020 | 6124 | 6122 |

| General lengthD(mm) | 2972 | 4876 | 5486 | 5918 | 6808 | 7570 | 8306 | 9296 | 9678 | 9704 | 9880 |

| Distance of import and exportE(mm) | 1752 | 2540 | 2768 | 3048 | 3810 | 4420 | 4954 | 5384 | 5562 | 5664 | 5664 |

| Center highF(mm) | 380 | 380 | 534 | 610 | 762 | 915 | 1066 | 1220 | 1220 | 1220 | 1220 |

| Total heightH(mm) | 762 | 838 | 1092 | 1270 | 1524 | 1778 | 2032 | 2362 | 2464 | 2566 | 2668 |

| Steam inletN(寸) | 3/4 | 3/4 | 1 | 1 | 1 | 1 | 11/2 | 11/2 | 11/2 | 11/2 | 2 |

| OutletO(寸) | 3/4 | 3/4 | 1 | 1 | 1 | 1 | 11/2 | 11/2 | 11/2 | 11/2 | 2 |

-

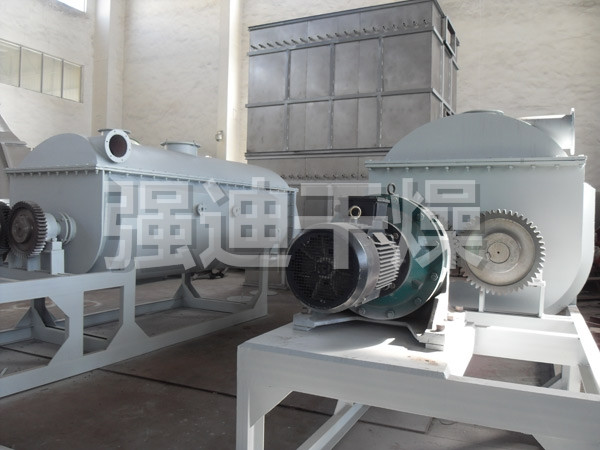

KJG hollow blade dryer

-

KJG hollow blade dryer

-

KJG hollow blade dryer

-

KJG hollow blade dryer

-

KJG hollow blade dryer

-

KJG hollow blade dryer

- 2017-12-27 > Dry modified starch production line

- 2016-08-04 > Xinjiang agricultural and sideline product net belt dryer delivery

- 2016-08-04 > Shenyang Chemical General plant has successfully ordered 4 large 96 square vacuum drying machines.

- 2016-08-04 > Qiang Di is drying with the Chinese Academy of Sciences, making two large flash dryer.

- 2016-08-04 > The hollow paddle dryer ordered by Qinghai Saline Lake has been successfully shipped

- 2016-08-04 > What trends should enterprises grasp to improve spray drying?

- 2016-08-04 > Liaoyang pigment factory orders our complete set of pigment drying equipment.

- 2016-08-04 > Improved vacuum dryer promotes green upgrading of bulk drug production

- 2016-08-04 > Necessary conditions for safe use of hot air circulating oven

- 2016-08-04 > The propeller machine industry is optimistic about the blade dryer

- 2016-08-04 > Why does the dry equipment industry don't see "Big Macs"