LZG Series Helix Vibrating Dryer

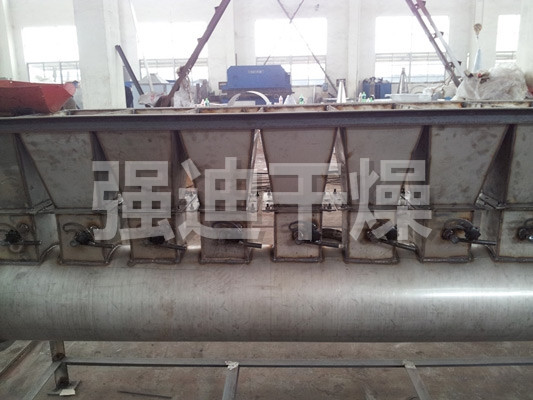

LZG Series Helix Vibrating Dryer

Product overview

The damp raw material enters into helix bed from feed inlet at the top and moves along with the helix bed under the function of excited force and gravity material make jumping motion from up to low until discharged at the bottom layer. Meanwhile clean hot air enters into it from the bottom of helix bed and carries out heat exchange with raw material fully and exhausts from the outlet at the top. In this way the drying purpose of damp raw material is reached.

Product application

The drier is mainly used for drying pill of Chinese traditional medicine. It can also be suitable for drying granule, strip and ball shape material of chemical industry, pharmaceutical industry, foodstuff industry, construction material industry, feed industry and so on.

Main features

1. Because the hot air passes through the raw material layer for many times and acts counter motion towards the raw material, the heat exchanges is fully used and thermal efficiency is high.

2. The structure is compact and it occupies small area.

3. The staying time of raw material in helix bed could be adjusted and the operation is very convenient.

4. Raw material acts the motion of circle at helix bed from up to low, meanwhile, the material is jumping, so the contact surface between hot air and raw material is increased and the drying effects is strengthened.

5. The equipment is suitable for continuous operation because of continuous feeding and discharging. Meanwhile it meet the requirement of GMP.

6. It does not damage the surface and shape of raw material basically. It can not only maintain the roundness of pill but also decrease the broken rate of pill.

Technical specifications

| Model | LZG-1.0 | LZG-1.2 | LZG-1.4 | LZG-1.6 | LZG-1.8 |

| Diameter (mm) | 1000 | 1200 | 1400 | 1600 | 1800 |

| Power (kw) | 2×1.1 | 2×1.1 | 2×1.5 | 2×1.5 | 2×2.2 |

| Overall size (m) | 1.2×1.2×2.7 | 1.4×1.4×2.7 | 1.6×1.6×3.3 | 1.8×1.8×3.3 | 2.0×2.0×3.3 |

| Weight (kg) | 1400 | 1680 | 2800 | 3100 | 3800 |

| Inlet air temperature (℃) | 60-200 | 60-200 | 60-200 | 60-200 | 60-200 |

| Amount of air(m3/h) | 1487 | 2380 | 3721 | 4462 | 5930 |

- 2016-08-05 > Xinjiang agricultural and sideline product net belt dryer delivery

- 2016-08-05 > Shenyang Chemical General plant has successfully ordered 4 large 96 square vacuum drying machines.

- 2016-08-05 > Qiang Di is drying with the Chinese Academy of Sciences, making two large flash dryer.

- 2016-08-05 > The hollow paddle dryer ordered by Qinghai Saline Lake has been successfully shipped

- 2016-08-05 > What trends should enterprises grasp to improve spray drying?

- 2016-08-05 > Liaoyang pigment factory orders our complete set of pigment drying equipment.

- 2016-08-05 > Improved vacuum dryer promotes green upgrading of bulk drug production

- 2016-08-05 > Necessary conditions for safe use of hot air circulating oven

- 2016-08-05 > The propeller machine industry is optimistic about the blade dryer

- 2016-08-05 > Why does the dry equipment industry don't see "Big Macs"