Industry news

Energy saving belt drying equipment used in drying of dyes

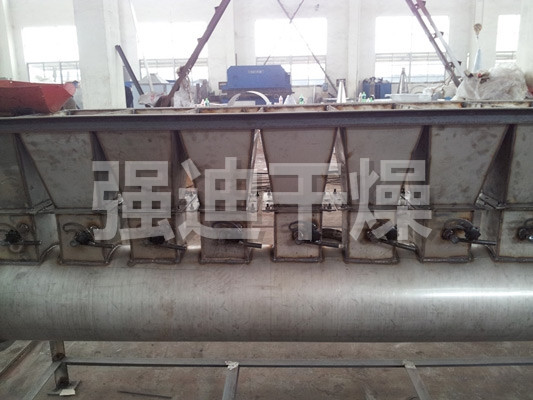

The dye belt drying equipment consists of quantitative feeder, molding machine, drying system, dehumidification and tail gas treatment system, industrial control system and so on.

Feeding machine:

The feeding belt is quantitatively fed, and the feed rate is adjusted by adjusting the belt speed.

Molding machine:

Shaping machine is the key in the process of pigment drying. If the pigment is uniform, it can greatly shorten the drying time, improve production efficiency and reduce consumption. Uneven molding will increase the drying time, at the same time, it will make the whole net surface not uniform, cause the hot air short circuit, the humidity temperature increase, waste energy, and the dust entrainment is serious, increase the load of the tail gas treatment device. Our company independently developed the design of the molding machine, can adapt to various working conditions, the use of special holes, the shape of the strip appearance is compact, clean, the appearance of the finished product is good.

Drying system:

The dryness system mainly solves the hot air problem, the drying cavity circulate hot air as far as possible in the whole net surface, so the design of the air return air position should be reasonable and avoid hot air short circuit, because in the drying process, the volume heat transfer coefficient is related to the wind speed of the material, and the volume heat transfer can be increased by the wind speed through the material. The drying capacity can be improved at constant speed drying stage. The windshield should be added on both sides of the mesh belt. As the resistance of the mesh belt increases after feeding, the hot air will probably be short-circuited from both sides of the mesh belt, and the drying efficiency will decrease. Therefore, selecting reasonable wind speed and setting effective air distribution device is the key to reasonable air intake.

The effective heat preservation of the box is to reduce the heat conduction directly to the outer wall in the dry cavity, and select the small heat conductivity and light aluminum silicate fiber felt, and pay attention to the gap treatment and the mosaic structure of the felt block.

Dehumidification and tail gas treatment system:

The size of the air exhausting air directly affects the energy consumption and production efficiency of the drying. The wet air volume assembly improves the productivity, but increases the energy consumption, so it is also important to choose the appropriate air discharge volume. Especially, the bad control of dehumidification in the front section will affect the drying time. Different materials, different moisture content, different dehumidification cycle must be strictly controlled. The exhaust gas is treated by two sets of independent systems. The humidity of the front exhaust is large and the water film is used to reduce dust.

Control system:

The whole set of equipment adopts automatic control system, and each part adopts linkage and interlock, which reduces the staffing and basically operates automatically in the operation process.

Our company has been devotes more than 20 years to design and manufacture all kinds of drying equipment, especially in the field of belt drier. We have our own unique design and experience. It is the domestic leader made by the belt type drying equipment. The belt dryer is not only used for pigment / dyestuff drying, but also widely used in many fields, such as food production. Our company designs details for each material to adjust equipment to ensure that it can maximize production efficiency and reduce consumption.

- 2017-12-05 > Xinjiang agricultural and sideline product net belt dryer delivery

- 2017-12-05 > Shenyang Chemical General plant has successfully ordered 4 large 96 square vacuum drying machines.

- 2017-12-05 > Qiang Di is drying with the Chinese Academy of Sciences, making two large flash dryer.

- 2017-12-05 > The hollow paddle dryer ordered by Qinghai Saline Lake has been successfully shipped

- 2017-12-05 > What trends should enterprises grasp to improve spray drying?

- 2017-12-05 > Liaoyang pigment factory orders our complete set of pigment drying equipment.

- 2017-12-05 > Improved vacuum dryer promotes green upgrading of bulk drug production

- 2017-12-05 > Necessary conditions for safe use of hot air circulating oven

- 2017-12-05 > The propeller machine industry is optimistic about the blade dryer

- 2017-12-05 > Why does the dry equipment industry don't see "Big Macs"