Location:Home / News / Industry news

Industry news

Technological innovations accelerate the improvement of drying efficiency

2017-01-08 | Browsing:

Changzhou Qiangdi drying equipment co., LTD.

Tags:Drying equipment, dryer

In the process of drug production, the treatment of materials is a key and important link, especially drying. Because many materials are thermal sensitive materials, it is very strict to control the temperature of the drying process. How to ensure that the pharmacodynamics of pharmaceutical raw materials are not damaged and at the same time effectively improve the drying effect has become the key to the drying technology.

The material processed in the pharmaceutical production is basically heat sensitive material, so in the drying process, we should avoid the material caking as much as possible, at the same time, improve the drying efficiency and shorten the drying time. In addition, in some special applications, the purity of the circulating gas in drying process may affect the quality of the final product.

Experts pointed out that in recent years, due to good market driven, the market trend of the drying equipment is stable and promising. In particular, some manufacturers with high technology content and fast product innovation are very popular. With the requirements of high quality, low energy consumption and environmental protection for the manufacturing industry of the pharmaceutical industry, the structure of the product is adjusted, the foundation of application R & D is rammed, and the development of new technology and new application fields has become the main goal of the development of the dry equipment field.

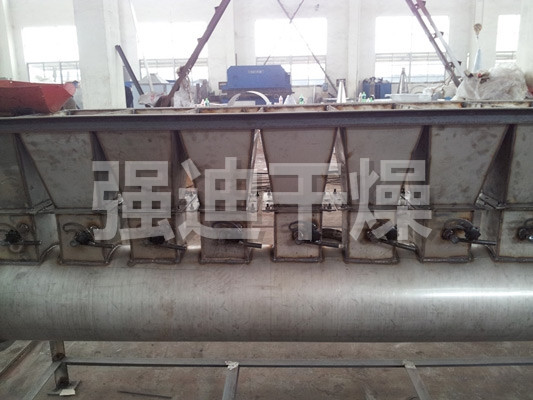

The traditional drying equipment has a single function and the comprehensive utilization efficiency of energy is not high. However, with the expansion of industrial production, especially in the pharmaceutical industry, production standards have been greatly upgraded, the requirements for comprehensive functions of the drying system are getting higher and higher. More and more attention has been paid to environmental protection and humanized operation. Design and performance are the core parts of the drying equipment. In the process of product design, all the variables that affect the parameter control of the product are paid more attention to, and the effect of heat transfer is further optimized through the vibro fluidized bed technology in order to improve the drying efficiency of the drying equipment.

Drying has always been a relatively large energy consumption link in the pharmaceutical production process, so energy-saving and environmental protection drying equipment has always been favored. In addition to increasing the application of energy saving technology, improving the efficiency of equipment and shortening drying time are also important methods. Therefore, the domestic dry equipment production enterprises accelerate the technical innovation of the industry, improve the drying efficiency of the products, and improve the production efficiency service will become the key of the enterprise leading market.

The material processed in the pharmaceutical production is basically heat sensitive material, so in the drying process, we should avoid the material caking as much as possible, at the same time, improve the drying efficiency and shorten the drying time. In addition, in some special applications, the purity of the circulating gas in drying process may affect the quality of the final product.

Experts pointed out that in recent years, due to good market driven, the market trend of the drying equipment is stable and promising. In particular, some manufacturers with high technology content and fast product innovation are very popular. With the requirements of high quality, low energy consumption and environmental protection for the manufacturing industry of the pharmaceutical industry, the structure of the product is adjusted, the foundation of application R & D is rammed, and the development of new technology and new application fields has become the main goal of the development of the dry equipment field.

The traditional drying equipment has a single function and the comprehensive utilization efficiency of energy is not high. However, with the expansion of industrial production, especially in the pharmaceutical industry, production standards have been greatly upgraded, the requirements for comprehensive functions of the drying system are getting higher and higher. More and more attention has been paid to environmental protection and humanized operation. Design and performance are the core parts of the drying equipment. In the process of product design, all the variables that affect the parameter control of the product are paid more attention to, and the effect of heat transfer is further optimized through the vibro fluidized bed technology in order to improve the drying efficiency of the drying equipment.

Drying has always been a relatively large energy consumption link in the pharmaceutical production process, so energy-saving and environmental protection drying equipment has always been favored. In addition to increasing the application of energy saving technology, improving the efficiency of equipment and shortening drying time are also important methods. Therefore, the domestic dry equipment production enterprises accelerate the technical innovation of the industry, improve the drying efficiency of the products, and improve the production efficiency service will become the key of the enterprise leading market.

相关文章

- 2017-01-08 > Xinjiang agricultural and sideline product net belt dryer delivery

- 2017-01-08 > Shenyang Chemical General plant has successfully ordered 4 large 96 square vacuum drying machines.

- 2017-01-08 > Qiang Di is drying with the Chinese Academy of Sciences, making two large flash dryer.

- 2017-01-08 > The hollow paddle dryer ordered by Qinghai Saline Lake has been successfully shipped

- 2017-01-08 > The dry equipment industry in China needs to be integrated in an all-round way

- 2017-01-08 > What trends should enterprises grasp to improve spray drying?

- 2017-01-08 > Liaoyang pigment factory orders our complete set of pigment drying equipment.

- 2017-01-08 > Improved vacuum dryer promotes green upgrading of bulk drug production

- 2017-01-08 > Changes in the market pattern of the drying equipment industry

- 2017-01-08 > Necessary conditions for safe use of hot air circulating oven

Relevant Products