Industry news

Market demand for airflow spray drying equipment

The product is the field of drying technology, which belongs to the category of thermophysical engineering. It is widely used in the pharmaceutical, biochemical, fine chemical, biological and other industries to be easy to oxidize. It contains the drying of liquid materials and the recovery of solvent. It has high efficiency, energy saving, low carbon emission reduction and economy. In this project, the application of nitrogen is a conductive heat transfer medium. At the same time, the closed circuit technology and the continuous production of airflow spray drying have been used to solve the technical problems of the liquid material containing organic solvents and the difficult drying of the oxidizing materials. At the same time, the condensing cooling technology is adopted in the continuous drying process and the condensing cooling technology is adopted. The recycling and utilization of organic solvent, on the basis of achieving industrial production emission reduction, shows the circular economy of maximizing resource utilization. This project also uses intelligent control and self diagnosis function. On the basis of improving the precision of equipment control, it also shows the automatic control degree of mechanical and electrical gasification, and achieves the management level of convenience, shortcut and modern production. The implementation of the project provides the infrastructure for energy saving and emission reduction for the economic development of the above industry, which optimizes the product structure, adjusts the economic development mode, and provides basic equipment and technical support for the development of new products.

With the good and fast development of China's economy, the demand for new drying technology is increasing increasingly. However, as far as China's dry technology progress is concerned, the overall technical level is still in a lagging state, and it is difficult to meet the economic development and product optimization of the related industries. Construction and demand for new product development. According to the market dynamic investigation and the related data, it is shown that most of China's pharmaceutical, biochemical, fine chemical industry and other industries have a vacuum entrainment heating in the dry production of liquid materials which are easy to oxide and contain organic solvents. With the vacuum drying and low boiling point (in the state of vacuum -0.085Mpa, when the heating temperature reaches 90 degrees C, the moisture is vaporized), and the oxidation resistance (the vacuum drying is heated by the jacket, the heat transfer gas is not directly contacted with the material, avoiding the problem of the product quality caused by the oxidation damage of the oxide material in the drying process). The advantage of it. Therefore, vacuum drying technology is still widely applied in the related industries. However, vacuum drying is a gap production with a single dosage, so its production capacity is greatly limited, while the gap production is difficult to achieve the recovery of organic solvents in the drying process. Therefore, it causes serious environmental pollution. Therefore, the vacuum drying technology is difficult to meet the optimized products in the related industries. Structure and new product research and development and industrial production needs.

With the progress of drying technology, the technology of spray drying closed circuit circulation has been studied in China. The core technology of this technology is to dry the liquid material of the suspension body by the form of centrifugal spray, but the radial speed of the centrifugal atomizer is slow (the speed of the atomizing disc is directly related to the volume of the atomizing disk, " Therefore, the liquid solid content of the centrifugal spray is limited to the range of 10~30%, so the speed of the centrifugal atomizing disk is 18000r/pm). Because of the low atomization solid content, it not only affects the production capacity, but also increases the energy consumption of dry production. The drying temperature is generally above 250 degrees C, and the quality of the finished product is obtained by the heating method of high temperature (because the atomization solid content is low, so the dried product is the powder structure). Therefore, high temperature heating not only increases the energy consumption, but also has a great potential accident for the drying of liquid materials containing organic solvents. In addition, centrifugal spray, because of its centrifugal effect, is very easy to cause droplet splashing to be bonded to the dry tower wall, causing the phenomenon of focal adhesion and wall sticking very seriously. And the technology does not have the function of solvent recovery and still exists the hidden danger of two pollution. Therefore, the centrifugal spray closed circuit technology can be in accordance with the high solid content sticky and thick suspension. The dry production of organic liquid materials and organic solvents should be further explored.

- 2017-03-31 > Xinjiang agricultural and sideline product net belt dryer delivery

- 2017-03-31 > Shenyang Chemical General plant has successfully ordered 4 large 96 square vacuum drying machines.

- 2017-03-31 > Qiang Di is drying with the Chinese Academy of Sciences, making two large flash dryer.

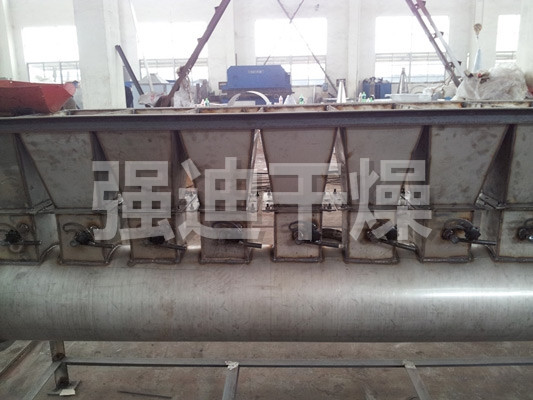

- 2017-03-31 > The hollow paddle dryer ordered by Qinghai Saline Lake has been successfully shipped

- 2017-03-31 > The dry equipment industry in China needs to be integrated in an all-round way

- 2017-03-31 > What trends should enterprises grasp to improve spray drying?

- 2017-03-31 > Liaoyang pigment factory orders our complete set of pigment drying equipment.

- 2017-03-31 > Improved vacuum dryer promotes green upgrading of bulk drug production

- 2017-03-31 > Changes in the market pattern of the drying equipment industry

- 2017-03-31 > Necessary conditions for safe use of hot air circulating oven