Loaction:Home / Products / Granulating/ GZL series dry rolling granulator

GZL series dry rolling granulator

GZL series dry rolling granulator

Tags:GZL series dry granulating machine, dry rolling granulator, dry granulator, granulator, granulator.

Nav:Granulating

Contents:Extrusion granulation is a relatively new process for producing compound fertilizers by dry granulation.

Product Details

Photo Gallery

Product overview

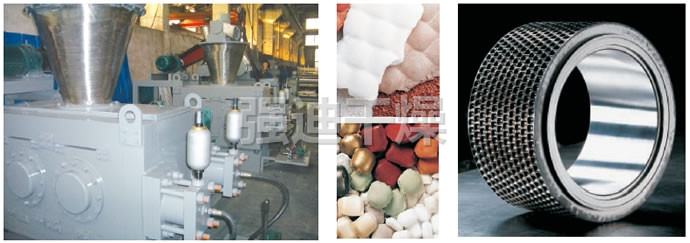

Extrusion granulation is a relatively new process for producing compound fertilizers by dry granulation. The extrusion granulation was first applied to the granulation of potassium chloride in the field of fertilizer, and the granular (1-4mm) potassium chloride needed for mixing fertilizer (BB fertilizer) was basically produced by extrusion. In recent years, extrusion pelletizing has been developed rapidly in domestic production of compound fertilizers.

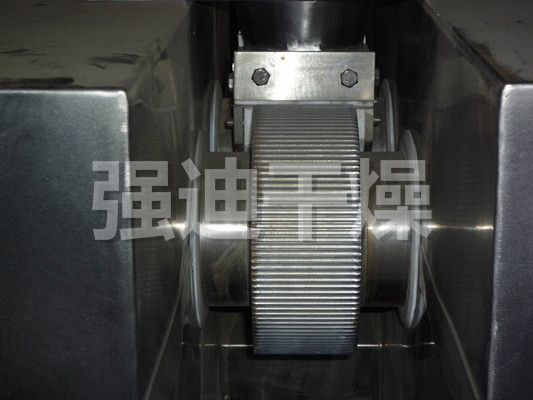

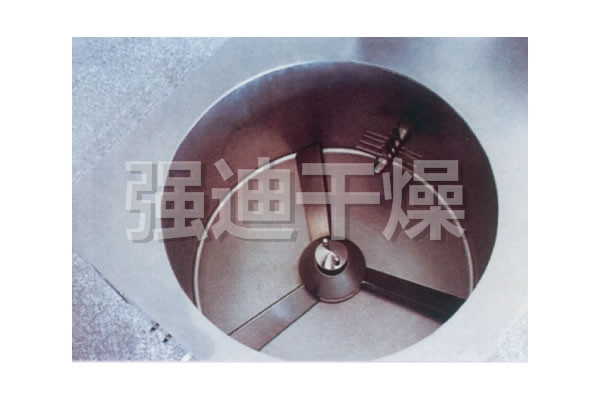

There are two kinds of roll type and wheel rolling type in the form of extrusion granulation. The roll extrusion is first pressed into large blocks and then broken into particles. This device has large capacity, high particle strength and low energy consumption, and is widely used abroad for roll extrusion. The wheel rolling is formed directly on the surface of the roller with the shape of a cavity, which is extruded into granules at once. When the strength of the product is low, it is sometimes necessary to add a binder. It is suitable for making organic manure and compound fertilizer.

Working Principle

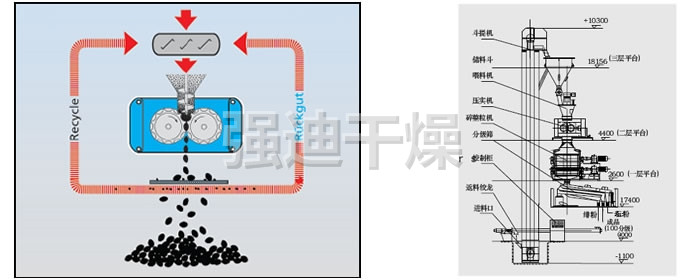

The process principle of roll extrusion granulation is that the dry material is assembled into dense and hard mass (cake material) under pressure, which is called the extrusion process, and the cake material is then crushed and sieved into granular material, which is called granulation process. The effect of extrusion is to squeeze air between particles, and to make the spacing of particles close enough to produce the attraction of Edward force, adsorption force, crystal bridge and embedded connection. Granulated particles are mainly formed by the force between molecules.

Technical Parameter

Extrusion granulation is a relatively new process for producing compound fertilizers by dry granulation. The extrusion granulation was first applied to the granulation of potassium chloride in the field of fertilizer, and the granular (1-4mm) potassium chloride needed for mixing fertilizer (BB fertilizer) was basically produced by extrusion. In recent years, extrusion pelletizing has been developed rapidly in domestic production of compound fertilizers.

There are two kinds of roll type and wheel rolling type in the form of extrusion granulation. The roll extrusion is first pressed into large blocks and then broken into particles. This device has large capacity, high particle strength and low energy consumption, and is widely used abroad for roll extrusion. The wheel rolling is formed directly on the surface of the roller with the shape of a cavity, which is extruded into granules at once. When the strength of the product is low, it is sometimes necessary to add a binder. It is suitable for making organic manure and compound fertilizer.

Working Principle

The process principle of roll extrusion granulation is that the dry material is assembled into dense and hard mass (cake material) under pressure, which is called the extrusion process, and the cake material is then crushed and sieved into granular material, which is called granulation process. The effect of extrusion is to squeeze air between particles, and to make the spacing of particles close enough to produce the attraction of Edward force, adsorption force, crystal bridge and embedded connection. Granulated particles are mainly formed by the force between molecules.

Technical Parameter

| Model | Center distance of roller | power |

| GZL-240 | 240 | 7.5-1.5 |

| GZL-360 | 360 | 22-45 |

| GZL-460 | 460 | 37-60 |

| GZL-580 | 580 | 45-90 |

| GZL-650 | 650 | 55-200 |

| GZL-730 | 730 | 90-315 |

-

GZL series dry rolling granulator

-

GZL series dry rolling granulator

-

GZL series dry rolling granulator

-

GZL series dry rolling granulator

Next:Period

Relevant News

No Relevant News...

Relevant Products